Have you been wondering what journey your pottery encounters after you leave your pottery class? This article describes the incredible process your pottery goes through from when you make your unique item in your pottery class at Driving Creek, to your pottery being delivered to your home.

Drying the Clay

After your class, and once you have moulded the clay into its final shape, the pottery is left to dry to ‘leather hard’. The initial drying process can take up to one week but varies based on how thick the clay is and even what the weather is like. Once the pottery reaches this semi-hard level, it is then trimmed by one of our Pottery Tutors to remove excess clay from the bottom and is then set aside to dry fully.

Bisque Firing

When the pottery is fully dry it is ready to be bisque fired in a kiln. A bisque firing is where the pots are fired, or more simply baked, in a kiln at 950°C. This firing removes any remaining moisture, which reduces the size by approximately 15%, and makes the pottery more durable and porous enough to absorb glazes.

The bisque firing also makes the pottery pieces stronger and more convenient for handling during the glazing process. The firing takes around 12 hours, and is then left for another 12 hours to allow the pottery to cool slowly.

The Art of Glazing

Once the pots are out of the bisque kiln they are ready to be glazed. Glazing is a truly amazing process where pottery comes to life by adding colour, texture and depth to the surface.

Glazes are made using minerals and oxides that add colour through colouring oxides such as cobalt, copper, iron, chrome, manganese, rutile, nickel, vanadium, and rare earths which are used in our range of pottery class glazes you were able to choose from. You can even change the way a glaze appears through different combinations, layering and techniques.

The glazing process is both a science and an art with many ways of applying a glaze from brushing and dipping, to spraying and pouring, each method alters the final result. The firing temperature, viscosity (thickness) of the glaze and atmosphere inside the kiln all play a role in the final outcome.

Glaze Firing

After the pottery is glazed it is then fired in the kiln for a second and final time. The second firing is called a ‘glaze firing’ and is where your pottery is fired for approximately 8.5 hours to slowly reach 1220°C. The specific temperature is to ensure the clay is vitrified (becomes a glass like substance) and the glazes are melted, creating a durable and beautifully finished piece of pottery.

The pottery is then left in the kiln for 2 days so it slowly cools before opening it to prevent cracking the pottery due to a sudden change in temperature.

The Unveiling

While the pottery cools the anticipation builds and the moment of truth arrives- the unveiling of the finished piece. What was once a ball of clay has been transformed into a work of art, rich in colour, texture and character. Each piece being uniquely handcrafted in your pottery class.

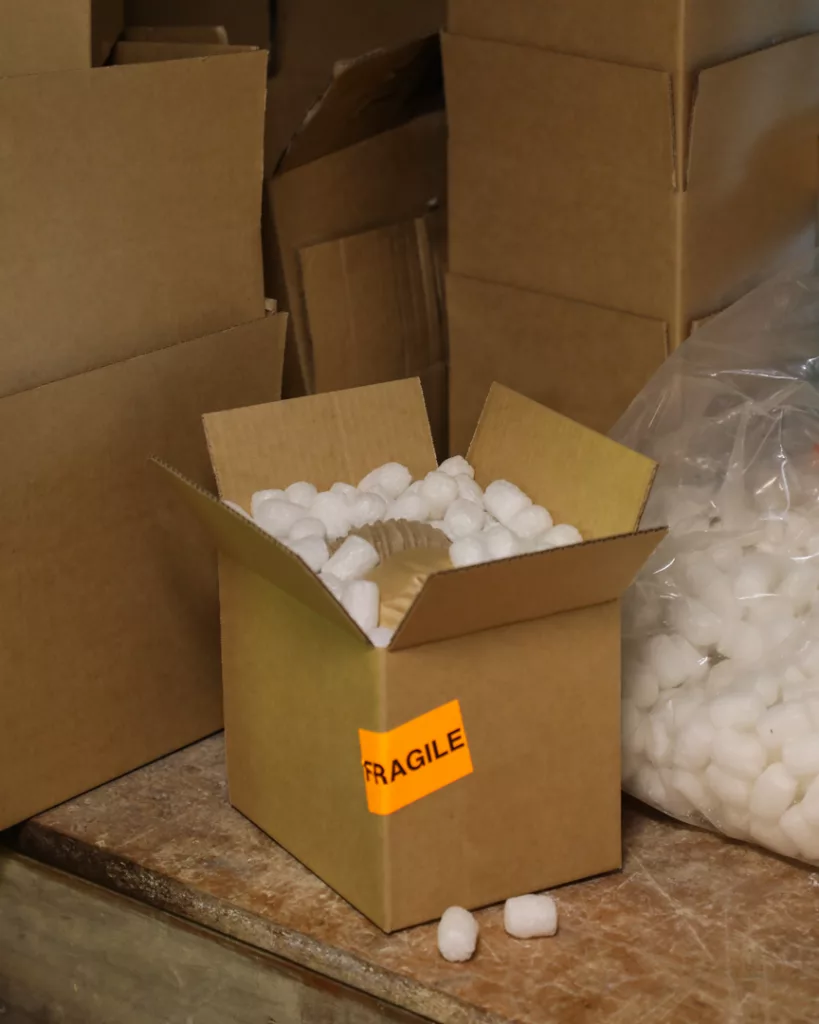

The pieces are then carefully packaged by our Pottery Tutors and picked up by the courier to be delivered to you to enjoy in your very own home!