Country: Italy

Field of Art: Ceramist

Instagram: @fango_ceramics

Jacopo Cucci, an Italian ceramist, embraces the playful nature of working with clay, choosing the name "Fango" (meaning "mud") to remind himself to have fun and explore through his craft. He creates unique, functional objects full of character and details that reveal themselves over time, using collected materials for sustainability and a personal connection to the materials. Jacopo specializes in stoneware, porcelain, and wild clays, mostly wheel-thrown, and enjoys atmospheric firings. He mixes his own glazes and has fired in wood kilns across Italy, Portugal, and Hungary, even building his own gas-powered kiln for soda firing. This residency is Jacopo's first and he is planning to start with clay, possibly digging or collecting some, and hoping to use the wood kiln and mini gama for firing of his work.

Country: UK

Field of Art: Ceramist

Instagram: @elliewoodspottery

We at Driving Creek Pottery are excited to welcome our first pottery apprentice Ellie Woods from Leach Pottery. Ellie Woods has worked as a pottery apprentice at Leach Pottery in Cornwall since the summer of 2021 learning production pottery full time. Over the past three years, she has mastered technical skills such as creating standard ware shapes, mixing glazes, and firing gas kilns, while also developing her own work. Ellie focuses on making functional stoneware pottery for everyday use. Eager to expand her practice, during her three month exchange at Driving Creek she is interested in exploring new environments, experimenting with different materials, and learning alternative methods of making and firing to further develop her work.

Country: New Zealand

Field of Art: Ceramist

Instagram: @_ferris_ceramics

Patrick Ferris is a New Zealand ceramic artist with a passion for clay that started in his youth. After studying at the Dunedin School of Art, where he graduated with a degree in Ceramics in 2022, his work has evolved to combine traditional pottery with digital techniques like 3D printing. Patrick enjoys sourcing his own materials, using local clays such as Temuka and experimenting with cullet for vibrant colors. He values sustainability and avoids harmful substances in his clays and glazes. His work focuses on functional pottery for everyday use, often wheel-thrown, with a particular interest in form and function. Currently, he is exploring a series of printed objects that warp and collapse in the kiln, aiming to create a wall installation and deepen his understanding of wood and gas firings, flashing, and bright colors. Driven by commercial success, Patrick is focused on creating pottery that is both beautiful and functional.

Country: UK

Field of Art: Sculptor

Instagram: @georgiahodierne

Georgia Hodierne is an emerging UK sculptor who creates vibrant, satirical sculptures that challenge societal norms and the unspoken rules of adulthood. Her work emphasizes the transformative power of play and aims to reconnect adults with curiosity and creativity, often overlooked in busy, work-centric lives. Through storytelling, her sculptures spark conversations and alternative perceptions, encouraging innovative ideas while rejecting the pressure to have all the answers.

Her creative process begins digitally, using sketches and Procreate to explore compositions before choosing materials that align with her conceptual ideas. She works primarily with paper pulp, paper clay, and ceramics, valuing non-traditional techniques to subvert fine art norms and embrace playful, absurd narratives. Her work draws on ancient civilizations, particularly ceramics, as a medium for storytelling, using humor and vibrant colors to challenge established cultural beliefs.

Georgia also values collaboration and community, seeking environments like the Driving Creek residency to exchange ideas and refine her skills. Currently, she is exploring the erotic ceramics of ancient Greece and their relevance to contemporary culture. Born in Wellington, New Zealand, and raised in England, she holds a BA in Fine Art Sculpture and is committed to creating, curating, and pursuing freelance projects. The residency offers her the ideal space to explore new artistic directions and deepen her practice.

Country: Denmark

Field of Art: Ceramist

Instagram: @bmorberg

Birthe Morberg Nielsen is a Danish ceramic artist returning to Driving Creek for her second residency. Birthe's work is deeply inspired by the natural surroundings at Driving Creek, she prefers the use of Coro Gold Clay processed on site for her pieces, and is hoping to participate in a wood and soda firing to capture the essence of plants, trees, and animals in their vibrant forms. Birthe's practice spans a wide range of ceramic expressions, from functional items like plates, mugs, and boxes, to more imaginative sculptures of animals, aeroplanes, and other objects. Her work often features a playful twist, incorporating humor and charm into each creation, inviting a lighthearted and engaging experience for viewers.

Country: India

Field of Art: Ceramist

Website: neetig.com

Instagram: @neetigoclay

Neeti Gokhalay Kheny is a Bangalore-based ceramic artist whose work is inspired by her deep connection to the sea and nature. With a Professional Diploma in Visual Communication from Srishti Institute of Art, Design and Technology, Neeti’s artistic journey is influenced by her experiences growing up in a merchant navy family, frequently traveling across the Atlantic, and becoming a certified Advanced Open-Water Diver. Her ceramic sculptures capture the intricate beauty of the underwater world, distilling these experiences into tactile forms that invite curiosity about aspects of nature that many may not often consider.

Neeti hand-builds her pieces, beginning with sketches and planning techniques before moving on to coiling, pinching, and ornamentation with slips and underglazes. Her work is characterized by bold designs, delicate textures, and the use of glazes that interact in creative ways. Firing her pieces in an electric kiln, Neeti documents the entire process, using images, videos, and notes to reflect on what works and what doesn't.

Currently at the beginning of her journey with clay, Neeti is eager to further explore and refine her artistic voice. She seeks to push the boundaries of her work by learning new techniques and experimenting with various firing methods, including wood and reduction firings. Neeti is particularly excited about the opportunity to engage with fellow artists at the Driving Creek residency, where she hopes to expand her understanding of clay, glazes, and firing processes, while developing a cohesive body of work that reflects her love for the oceans and nature.

Exhibition curated by Karl Fritsch

The NOTTAPOTTA exhibition at Driving Creek Gallery is a tribute to the visionary artist, potter, and conservationist Barry Brickell. More than just a showcase of his diverse art collection, this exhibition immerses visitors in Barry’s unique way of thinking and creating—his philosophy of process over outcome, encapsulated in his ethos: “It’s not the thing, but how.”

At the heart of NOTTAPOTTA are Barry’s writings—or as he called them, “wrertings”—a playful and deeply personal form of expression that captures his musings on art, nature, life, and the trains that became such a central part of his world. These words, painted in sloppy clay on the gallery walls, form the base layer of the exhibition, setting the tone for the artworks displayed around, on, and over them.

Barry Brickell was not only a prolific artist but also a passionate collector, gathering pieces that resonated with him over the years. Notta Potta features an eclectic mix of styles and approaches, from paintings acquired from local artists to works gifted by renowned national and international creatives who visited Driving Creek. Many of these artists were drawn to Barry’s unique environment, staying, working, and creating in a space where art and nature intertwined seamlessly.

This exhibition offers a rare glimpse into Barry’s world—one where art was not just about the finished product, but about the journey of creation itself. Whether you are familiar with Barry’s legacy or discovering his work for the first time, NOTTAPOTTA invites you to engage with his vision in a deeply immersive way.

Exhibition Details:

📍 Location: Driving Creek Gallery

🕒 Opening Hours: Tuesday – Sunday, 11 AM – 3 PM

📅 Closing Date: February 29, 2025

Don’t miss this opportunity to explore the artistic mind and collection of one of New Zealand’s most beloved creative figures. NOTTAPOTTA is more than an exhibition—it’s an experience of Barry Brickell’s enduring spirit.

Country: New Zealand

Field of Art: Ceramist/Art Educator

Website: www.connectthedots.org.nz

Introduction:

Andrea Gaskin is an artist and arts educator committed to removing barriers to arts participation and celebrating diverse visual languages. She has focused her practice on arts education, particularly in the areas of brain injury and dementia, and now aims to expand her own artistic journey. A passionate hand builder, Andrea has years of experience in both practicing and teaching handbuilding techniques, valuing the individual expression that each maker brings to the craft. She has held a residency at Studio One Ponsonby in Auckland and integrates her pottery skills into her charity, Connect the Dots. Andrea is soon visiting India to explore combining pottery with textiles, particularly through block printing. Her goals include dedicating uninterrupted time to her pottery practice and connecting with like-minded artists.

Country: New Zealand

Field of Art: Ceramist

Instagram: @samdmakes

Introduction:

Sam Dickenson is a passionate ceramic artist who discovered his love for pottery as a teenager. She went on to study ceramic design at Central St Martins and spent five years designing and creating pottery in London before relocating to Auckland in 2007. After a break from her practice due to family commitments, Sam has returned to ceramics with the support of the Auckland Studio Potters. She now explores handbuilding, working with slabs, plaster, and ceramic molds made from found and self-created forms. Sam enjoys creating functional pieces like mugs and platters, valuing the experience of using and enjoying his work. She aims to loosen up creatively, connect with the community, and embrace a fun, open-minded approach to his craft.

Country: United Kingdom

Field of Art: Sculptor

Instagram: @georgiahodierne

Introduction:

Georgia Hodierne is an emerging sculptor whose work challenges societal norms through vibrant, satirical sculptures. Her practice explores the transformative power of play, reconnecting adults with their innate curiosity amidst a fast-paced world. By questioning culturally established narratives and offering playful, absurd scenarios, Georgia invites alternative perspectives and fosters conversation. She combines her background in digital drawing and collage with material choices like paper pulp, clay, and paper mache, which she uses to create pieces that subvert traditional art forms. Drawing inspiration from ancient civilizations and the role of ceramics in storytelling, her work conveys humor and challenges norms. Passionate about collaboration, she is eager to contribute to communities like Driving Creek, where creative exchange thrives. Currently, she is exploring the artistry of ancient Greek erotic ceramics, aiming to contextualize these historical creations in a contemporary setting. Raised in England and born in Wellington, New Zealand, Georgia has completed her BA Hons in Fine Art Sculpture and is actively pursuing creating artworks while curating shows and engaging in freelance projects.

Country: United States

Field of Art: Ceramist

Website: www.girlpots.com

Instagram: @girlpots

Introduction:

Sasha Polonko, founder of Girl Pots, is a Costa Rican-American ceramicist based on Whidbey Island. Her work is deeply rooted in sustainability and her connection to nature, reflecting her Costa Rican heritage. Sasha creates her own glazes and clays from raw materials she forages locally and globally, with a focus on durability, comfort, and beauty. Influenced by pre-Columbian ceramics, particularly from Costa Rica, Sasha blends contemporary pottery with ancient aesthetics. She experiments with found clays and natural glazes, sometimes combining them with commercial products. Her process involves gathering materials, developing clay bodies and glazes, and choosing firing methods that best honor the materials. Sasha is eager to explore pre-Columbian pottery techniques further, aiming to create a collection using locally sourced materials and traditional firing methods.

Country: New Zealand

Field of Art: Multi-disciplinary Artist

Instagram: @cindyhuang.studio

Introduction:

Cindy Huang is an interdisciplinary artist whose work spans installation, painting, performance, and social sculpture, exploring themes of exchange, generosity, and adjacency. Her research delves into the histories of Chinese migrant communities in Aotearoa New Zealand, particularly the relationships between Māori and Chinese communities. Huang's practice includes large-scale installations that blend ceramic sculptural objects with social engagement and community building. She draws from historical accounts of Chinese life in Aotearoa and the concept of being tangata tiriti. Currently, Cindy is focused on expanding her studio practice, particularly in clay, and is developing a new body of work exploring migrant relationships with the landscape, blending regional New Zealand painting with Shan Shui (Chinese Mountain Water) aesthetics and personal identity.

Country: Sweden

Field of Art: Ceramist

Website: clayspacestockholm.com

Instagram: @clayspace.stockholm

Introduction:

Yvonne Matstoms is a Swedish ceramic artist whose creative journey began after the loss of her spouse, finding solace and purpose in clay. She feels strongly that art and to creativity is a true connection with the mystery and the greater in life.With a background in art history and a deep aesthetic appreciation, she realised her own artistic potential later in life. Yvonne draws inspiration for her work from organic forms, the Arts and Crafts movement, archaeological findings, and Japanese everyday ceramics. Yvonne primarily creates functional, beautiful items like bowls and vases, blending several techniques such as throwing, coiling, and slab-building in her work. Her goal is for her work to be cherished and displayed, even when not in use. Currently, she’s exploring sculpture, particularly a series inspired by the need for protection in today’s turbulent world, including sculptures of angels and swans symbolizing strength and blessings.

Country: Australia

Field of Art: Ceramist

Website: silvesterart.com

Instagram: @silvesterart

Introduction:

Sara Buchner (SilvesterArt) is a multidisciplinary artist whose work is inspired by dreams, creating small, heartfelt illustrations and prints. Drawing from the Wiener Werkstätte and the publication Ver Sacrum, her pieces blend clean lines with narrative, resulting in expressive and animated works. Sara incorporates discarded materials, like scrap wallpaper and linoleum offcuts, into her watercolors and linocuts, adding a surreal, everyday quality to her art. Her printmaking utilizes non-toxic ink on small-scale lino and plywood blocks, while her ceramics feature slab-built, architecturally inspired sculptures, vases, and planters. Sara is currently focusing on incorporating native plant motifs and landscape-inspired sculptures into her ceramic work and was looking to explore new mediums and techniques during her residency at Driving Creek.

By Holly Morgan

Nestled amongst the rolling hills and lush trees in the coromandel, a group of eager clay workers from around the country gathered at the iconic establishment Driving Creek Railway (DCR). Connected by a material, excitement built as we were about to embark on a five day Onggi Masterclass by Korean Master Kwak Kyung Tae & Marco Minetti. The class was nothing short of masterful, filled with eloquent techniques designed to gain an in-depth understanding of the ancient art of making Onggi. My hands are trained in production potting (on the potter's wheel) and each day we were challenged with new interesting skills that by the end of the course we could string together to give us a base level of training to take back to our studios to practice.

Day one, this was spent making very long coils, I particularly found this step quite satisfying. Stretching otherwise solid particles of dirt and water and forming them into 8 sided faceted 'noodles' that we could carry, stack, sling and slide along our hands. Slowly. At the end of the first day, I knew that it was just the beginning and we got a glimpse into the level of detail Kwak and Marco had put into the course. I could tell from the outset that the week was going to be challenging, fun, and inspiring.

Day two, things turned up a notch, our hands really went to the gym and I found myself dreaming about Onggi and waking up at 2am to massage kawakawa balm into my hands. We went on to making our bases, adding our first coils, and were introduced to 'taryeom jil' the art of attaching the coils. It's within this particular technique that I believe holds one of the special charms in making Onggi. When proficient, you have the ability to build forms in a day and manipulate the clay in a way that gives the work structure, height and support with a relative speed. For me, and others when I asked around - this was the most challenging step in the process. I felt very grateful to have been given the opportunity to have it broken down and spelled out. Even so, I felt like my brain couldn't connect to my hands and it wasn't until the last day that I felt a sense of ease. Maybe it was because i'd been beaten into conformity, like the wall of an Onggi pot. Onggi 1 Holly 0.

The following days merged into the melting pot, our guards dropped and with a couple of social evenings cooking pizza under the starry sky, and sharing meals huddled around Barry's Kauri slab table things felt like they were just warming up. We sunk into a rhythm, and the dedication, commitment and focus was unanimous amongst our group of ten. Participants often slipped into class before the day started or skipped half of lunch to head in early to get a couple of extra coils under their belt so to speak. Attaching the coil was a complex yet visually simple motion which involves the slide and movement of both hands working in unison. Squeeze, slide, rotate, up, compress, fill, lock, attach, okay adjust, now the next 1cm. What the videos you see online don't highlight, is the generational knowledge and the sense of feeling and connection with the clay. The material that we are all so familiar with, now being used in a rhythmic dance. I wonder if Kwak ever switches off and allows his mind to wonder?

The final steps of making onggi was to use the su-rae and do-ge to shape and form the jar. When thinking back, getting the hang of this technique was largely about sound as it was how the tools were used. Steady hands grasp hand shaped tools, pop pop pop. The items had been designed by Kwaks teacher and had been soaking in water for a few weeks to add weight. pop pop pop ''Too much power' 'more power' striking a fine balance to create equal amounts of pressure to let the tools bounce and peel off the clay. A seismic meditation. Before long, voluminous bellies emerged each with the motion and essence of the creator or creators in some instances. As someone who feels comfortable exploring large round forms, I've described working away on pieces similar to these as 'therapy pots' so many tiny moments and opportunities for them to take on a life while you're spending time with them. It wasn't all smooth grooves and sunshine, there were moments when you thought that maybe things weren't going too well - and it was amazing to see what a few slaps from your hands on the walls of the vessel could do to improve the shape so you could carry on. Many in the class got to take home a couple of jars by the last day, it was so cool to see the progress. As I'm a slow hands on learner, I took my time and ended up with one larger form which I named 'hand holiday' - mostly because it was not. And to be honest, I snuck off to throw a pot at one point to make sure my hands did still remember what to do. They did - phew!

The whole process had a symbiotic rhythm and movement to it, just like wheel throwing when you get it, you can make it look easy. Fluid tai chi motions when stretching the coils, through to the transfer of energy between you and a lump of earth. It's beautiful, mesmerising and easy to let the world around you slip away. Kwak and Marco were wonderful teachers, Kwaks dedicated approach with humour and delight in the craft accompanied by Marcos' patience, kindness and lightness complimented each other and their approach. They made the participants feel at ease to make mistakes and instilled the confidence to try something completely new and out of their comfort zone. Moreover, aside from our basic Onggi training, we were shown ways for us to see how these new techniques could be used in modern and contemporary ways - re-thinking the way we approach the material. As the dust settles in a pink haze I'm enthused and excited to introduce my new tools to my studio and see what I can do from attending this course. I feel like I've been rewired, and with a small evening practising since the course ended - I can't look at coils in the same way. With the limited time that we did have, I know that the Korean ceramic history is rich and deep - while I know i've only brushed the surface, I do hope to one day make it to Korea to first hand experience Onggi in their homeland and to learn more about this ancient art.

Have you been wondering what journey your pottery encounters after you leave your pottery class? This article describes the incredible process your pottery goes through from when you make your unique item in your pottery class at Driving Creek, to your pottery being delivered to your home.

After your class, and once you have moulded the clay into its final shape, the pottery is left to dry to ‘leather hard’. The initial drying process can take up to one week but varies based on how thick the clay is and even what the weather is like. Once the pottery reaches this semi-hard level, it is then trimmed by one of our Pottery Tutors to remove excess clay from the bottom and is then set aside to dry fully.

When the pottery is fully dry it is ready to be bisque fired in a kiln. A bisque firing is where the pots are fired, or more simply baked, in a kiln at 950°C. This firing removes any remaining moisture, which reduces the size by approximately 15%, and makes the pottery more durable and porous enough to absorb glazes.

The bisque firing also makes the pottery pieces stronger and more convenient for handling during the glazing process. The firing takes around 12 hours, and is then left for another 12 hours to allow the pottery to cool slowly.

Once the pots are out of the bisque kiln they are ready to be glazed. Glazing is a truly amazing process where pottery comes to life by adding colour, texture and depth to the surface.

Glazes are made using minerals and oxides that add colour through colouring oxides such as cobalt, copper, iron, chrome, manganese, rutile, nickel, vanadium, and rare earths which are used in our range of pottery class glazes you were able to choose from. You can even change the way a glaze appears through different combinations, layering and techniques.

The glazing process is both a science and an art with many ways of applying a glaze from brushing and dipping, to spraying and pouring, each method alters the final result. The firing temperature, viscosity (thickness) of the glaze and atmosphere inside the kiln all play a role in the final outcome.

After the pottery is glazed it is then fired in the kiln for a second and final time. The second firing is called a ‘glaze firing’ and is where your pottery is fired for approximately 8.5 hours to slowly reach 1220°C. The specific temperature is to ensure the clay is vitrified (becomes a glass like substance) and the glazes are melted, creating a durable and beautifully finished piece of pottery.

The pottery is then left in the kiln for 2 days so it slowly cools before opening it to prevent cracking the pottery due to a sudden change in temperature.

While the pottery cools the anticipation builds and the moment of truth arrives- the unveiling of the finished piece. What was once a ball of clay has been transformed into a work of art, rich in colour, texture and character. Each piece being uniquely handcrafted in your pottery class.

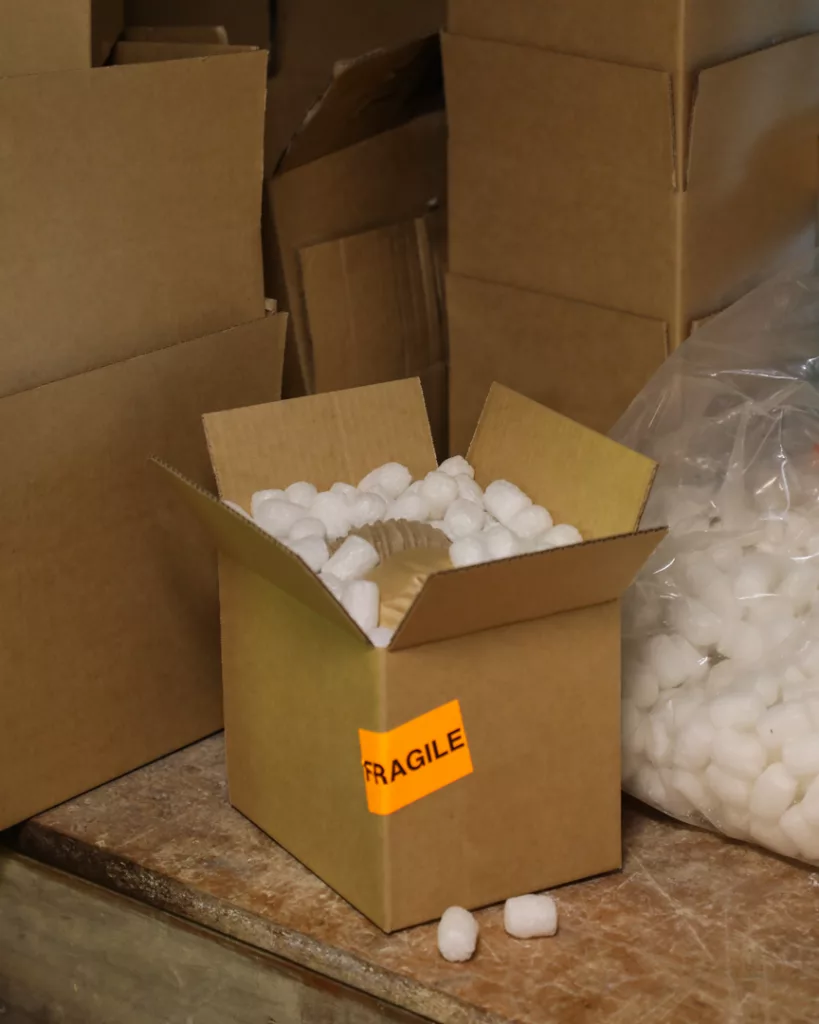

The pieces are then carefully packaged by our Pottery Tutors and picked up by the courier to be delivered to you to enjoy in your very own home!